Result

Digital Twin

Practical digital twin reference architecture

The Digital Twin workstream gave members of CBA Lab a digital twin reference architecture that can be used in all industrial sectors. The ability to achieve such a multi-sector solution was due to the fact that companies from diverse sectors, such as the automotive, household appliances, and optics industries, participated in the workstream.

All of these industries can work with the reference architecture, as is confirmed by Britta Boldt, an enterprise architect from Volkswagen Konzernlogistik GmbH & Co. OHG who participated in the workstream. “We are going to use this reference architecture,” says Boldt, adding that if not for CBA Lab’s cross-industrial approach and the effective cross-industrial collaboration among the workstream participants, the Digital Twin workstream would never have been able to achieve such a good result.

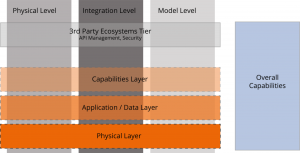

The reference architecture that was developed (see the chart on the next page) consists of three vertical levels (Physical, Integration, and Model) and a special separate level (Overall Capabilities). This level includes capabilities such as lifecycle management, mobile device management, AI, machine and deep learning, big data, and other overlapping functionalities, whereby the latter are available to the entire IT organization at a company – and not just to the digital twin.

The Capabilities, Application/Data, and Physical layers are arranged across the vertical levels. The Physical-level section of the Capabilities layer includes diagnostics, lifecycle status, and edge logic / analytics, for example. These react on the Integration level with / are monitored using capabilities such as data management, workflow management, and API management. A fourth layer – the 3rd Party Ecosystem tier – ensures security and API management across all levels.

“The exceptional quality of the reference architecture is due to the fact that it can be used within a company not only to develop digital twins and compare solution components from different providers but also as a basis for collaboration in a partner ecosystem,” says Dr. Verena Schmidtmann, who managed the Digital Twin workstream and is also a partner at Detecon.

For example, if a company purchases a machine for a production line, this machine is usually now delivered with a digital twin and needs to be integrated into the existing digital twin landscape. In such a situation, Schmidtmann explains, the reference architecture serves as a neutral coordination framework that simplifies the integration of digital twins into their environment. “However, the results of the workstream don’t solve all integration issues, of course,” says Schmidtmann.

“In terms of semantics in particular, some pieces of the puzzle are still missing – especially standards from protocol providers such as the OPC Foundation and semantics providers like eClass, umati, and the Administration Shell of Plattform Industrie 4.0. Nevertheless, it’s already clear that enterprise architecture is the discipline that will provide the structure for these integration tasks.”

The reference architecture serves as a neutral coordination framework that simplifies the integration of digital twins into their environment.

Along with the reference architecture, the workstream also developed a demonstrator. The demonstrator made it possible to examine the reference architecture’s benefits and drawbacks not only from a theoretical perspective but also in practical terms. The demonstrator also made it possible to explain the benefits of the architecture to those who know little about such systems.

The demonstrator was created with the help of two Raspberry PI single circuit boards and the IoT Cloud from Bosch.

It shows how the digital twin of a refrigerator installed in an electric camper van improves the energy management of the overall system.

An integrated dashboard also makes it possible to monitor and control actuators and control loops. “This demonstrator helped us a lot in terms of moving away from an abstraction because it enables haptic perception of the digital twin and its effects,” Boldt explains.

In other words, the activities conducted in the workstream made it possible for workstream participants and CBA Lab members to physically experience and thus clearly understand the digital twin concept.

Boldt believes the workstream resulted in three key takeaways:

- The reference architecture – makes it possible to use the digital twin in different industrial sectors.

- The demonstrator – presents the benefits offered by the digital twin in a clear and understandable manner.

- Cross-industrial collaboration – works perfectly at CBA Lab because workstream participants focus intensely on workstream tasks and are extremely committed to achieving good results.

CBA Lab’s cross-industrial approach and the effective cross-industrial collaboration among the workstream participants are what enabled the achievement of such a good result.

Please also read the professional article on this topic "Standards for digital twins"

Download the study "Digital Twins – Leading the Way to Tomorrow’s Ecosystems"

Deutsch

Deutsch  English

English